The Ultimate Guide to Picking the Right Mass Containers for Your Service Requirements

Choosing the suitable mass containers is essential for any kind of service that counts on effective logistics. Various types of containers exist, each made for certain materials and applications. Aspects such as dimension, material compatibility, and regulative criteria play a considerable duty in this decision-making process. Understanding these components can bring about improved functional efficiency. However, lots of services forget necessary aspects that can enhance their overall efficiency and sustainability. What are these factors to consider?

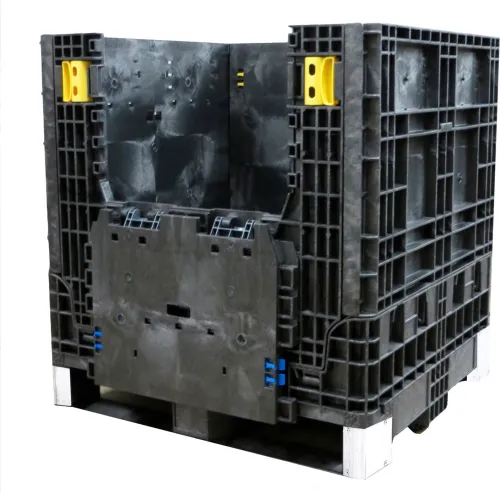

Understanding Different Kinds of Bulk Containers

Mass containers offer as important tools for services looking for efficient storage and transport solutions. These containers come in different kinds, each designed to meet specific operational needs. One typical kind is the intermediate mass container (IBC), which is optimal for granulated and liquid products, supplying a balance of capacity and ability to move. An additional prominent choice is the mass bag, or FIBC, appropriate for dry, flowable items. These adaptable containers are lightweight and can be easily moved and saved. For much heavier products, rigid mass containers are typically used, supplying resilience and security for secure handling. In addition, there are specific containers customized for harmful products, ensuring conformity with safety and security laws. Recognizing the distinctive attributes of these mass container types allows organizations to make educated decisions that enhance logistics and minimize prices. By selecting the ideal container, business can improve their operational effectiveness and streamline their supply chain processes.

Secret Product Considerations for Bulk Containers

When choosing bulk containers, it is necessary to ponder the materials used in their construction. Variables such as toughness, chemical, and resilience compatibility play an essential role in making certain the containers satisfy particular functional needs. In addition, weight and portability issues can affect both performance and transportation logistics.

Material Toughness and Stamina

Longevity and toughness are important factors in selecting products for mass containers, as they straight affect the container's capacity to stand up to various ecological conditions and managing procedures. Products such as high-density polyethylene (HDPE), polypropylene, and stainless-steel are frequently preferred for their durable residential properties, offering resistance to impact, temperature, and abrasion changes. The choice of product also influences the overall life expectancy of the container; more powerful materials generally cause much less frequent replacements, resulting in set you back savings over time. In addition, the weight of the product can affect shipping prices and simplicity of handling. Businesses have to consider their specific operational environments and the capacity for wear and tear to guarantee peak durability and strength in their mass container option.

Chemical Compatibility Aspects

Understanding chemical compatibility is necessary for picking mass containers, as the products made use of have to stand up to the details substances they will hold. Various variables affect compatibility, including the chemical nature of the components, temperature, and duration of storage space. As an example, corrosive chemicals may call for containers made from stainless-steel or specialized plastics that resist degradation. Additionally, responsive materials can produce warm or gases, demanding aired vent or pressure-rated containers. The selection of container product, whether steel, polyethylene, or polycarbonate, need to line up with the chemical residential properties of the kept substances to protect against leakages or breaches. Inevitably, an extensive assessment of these compatibility variables assures risk-free handling and storage, safeguarding both workers and the atmosphere while keeping product integrity.

Weight and Transportability Concerns

Selecting mass containers entails not only reviewing chemical compatibility but likewise considering weight and mobility. Organizations have to examine the ease of handling and transport to maximize effectiveness. Light-weight products like high-density polyethylene (HDPE) or light weight aluminum can facilitate simpler motion and reduce shipping costs. Alternatively, much heavier containers may supply boosted toughness however can impede movement, specifically in environments needing constant moving. In addition, the design of the container ought to enable convenient lifting and piling, making sure ergonomic security for workers. Business should also consider the facilities offered for transportation; for instance, containers compatible with forklifts or pallet jacks can simplify operations. Ultimately, the ideal equilibrium between weight and mobility straight affects operational efficiency and cost performance.

Sizing Your Mass Containers for Ideal Effectiveness

When sizing bulk containers, businesses must thoroughly examine the dimensions called for to suit their details items. Furthermore, weight ability is a crucial element that affects performance and security throughout transport and storage. Efficient sizing not just takes full advantage of area however likewise enhances operational workflows.

Figuring Out Container Capacities

Choosing the best measurements for mass containers is crucial for optimizing efficiency in storage space and transport. Organizations need to analyze their details requirements, considering variables such as offered space, the nature of the products being saved, and the approaches of transportation used. Precise measurements assure that containers fit ideally in storehouses and cars, reducing wasted area and lowering taking care of time. Requirement dimensions can offer benefit, yet custom dimensions may be needed for special demands or to fit specific products. Furthermore, it is essential to assess stacking capacities and availability, as these aspects affect overall operational performance. Eventually, the appropriate dimensions bring about enhanced company and streamlined logistics, profiting the total efficiency of the organization.

Weight Capacity Considerations

Comprehending weight ability is important for businesses aiming to enhance their mass container performance. The weight ability of a container directly influences storage capabilities, transportation logistics, and overall functional expenses. Selecting containers with the appropriate weight limitations ensures that services can securely save and transfer their items without running the risk of damage or compliance concerns. Overwhelming containers can cause structural failures, while underutilizing capability results in squandered resources. It is essential for organizations to analyze their product weights and think about any type of regulative needs when picking containers. In addition, variables such as the kind of product, planned usage, and environmental conditions should also affect weight capability decisions. By assessing these elements, companies can improve performance and assure a structured supply chain.

Regulatory Conformity and Safety And Security Specifications

Regulative conformity and safety requirements click here play a crucial function in the selection of bulk containers for services. Organizations has to assure that their containers satisfy numerous regulations established by neighborhood, national, and international authorities. These requirements frequently relate to product safety, architectural integrity, and correct labeling, which aid protect against crashes and ensure the safe transport of goods.

In addition, adherence to industry-specific standards, such as those from the Fda (FDA) or the Occupational Safety And Security and Health Management (OSHA), is essential for companies dealing with dangerous products or food. Non-compliance can cause penalties, legal issues, or damage to a business's reputation.

Companies must additionally consider the container's compatibility with the materials being stored or moved to avoid contamination or chemical reactions (used bulk containers). To summarize, comprehending and carrying out governing conformity and safety standards is necessary for the efficient and accountable use bulk containers

Sustainability Options for Eco-Friendly Mass Containers

Business are likewise checking out choices made from recycled products, which not only conserve sources but additionally sustain the reusing market. Developments in layout allow for lighter containers that require much less energy to transport, even more improving sustainability. By incorporating these environment-friendly mass container alternatives, organizations can demonstrate their commitment to environmental stewardship while fulfilling customer demand for sustainable methods. This shift not only aids the world however can also improve brand name reputation and customer commitment.

Cost-Effectiveness and Budgeting for Bulk Containers

While lots of businesses concentrate on sustainability, cost-effectiveness stays a vital aspect when picking bulk containers. Organizations needs to evaluate the initial acquisition rate, along with long-lasting operational costs, to assure monetary feasibility. Aspects such as longevity, reusability, and maintenance play a significant function in figuring out total expenditures.

Purchasing high-quality containers may yield higher ahead of time expenses yet can cause cost savings via decreased substitute rates and reduced waste. In addition, companies must consider transport costs and storage performance, as these can influence the general budget plan.

Often Asked Concerns

Exactly how Do I Establish the Right Container for Hazardous Products?

To determine the ideal container for unsafe products, one must assess compatibility with the compound, take into consideration the container's product, look for regulatory conformity, and assess capacity and safety and security functions to ensure appropriate handling and storage.

Can Bulk Containers Be Personalized for Specific Products?

Yes, bulk containers can be customized for specific items. used collapsible bulk containers. Numerous features, such as product, layout, and size, can be customized to meet distinct requirements, making sure suitable safety and effectiveness for delivering and storing different products

What Is the Ordinary Life-span of Various Mass Container Kind?

The average life expectancy of bulk container kinds varies; plastic containers last 5-10 years, metal containers 10-20 years, and wood containers commonly last 3-7 years, depending on use, upkeep, and environmental problems.

Just how Should I Clean and Maintain Mass Containers?

To cleanse and preserve bulk containers, one must regularly examine for damage, remove deposit, laundry with ideal cleaning agents, rinse extensively, and assurance correct drying prior to storage space. Complying with manufacturer standards enhances durability and safety and security throughout usage.

Exist Rental Choices for Bulk Containers Available?

Yes, many companies provide rental options for mass containers, offering flexibility for companies. These rentals can fit numerous demands, allowing firms to manage stock efficiently without the commitment of purchasing containers outright.

Sturdiness and toughness are crucial variables in picking products for mass containers, as they straight influence the container's capacity to stand up to various ecological conditions and taking care of procedures. Understanding chemical compatibility is vital for choosing mass containers, as the products made use of must resist the particular compounds they will hold. Recognizing weight capability is essential for organizations aiming to maximize their bulk container efficiency. Regulative conformity and security criteria play a necessary duty in the option of bulk containers for organizations. While numerous organizations focus on sustainability, cost-effectiveness continues to be a vital aspect when picking mass containers.